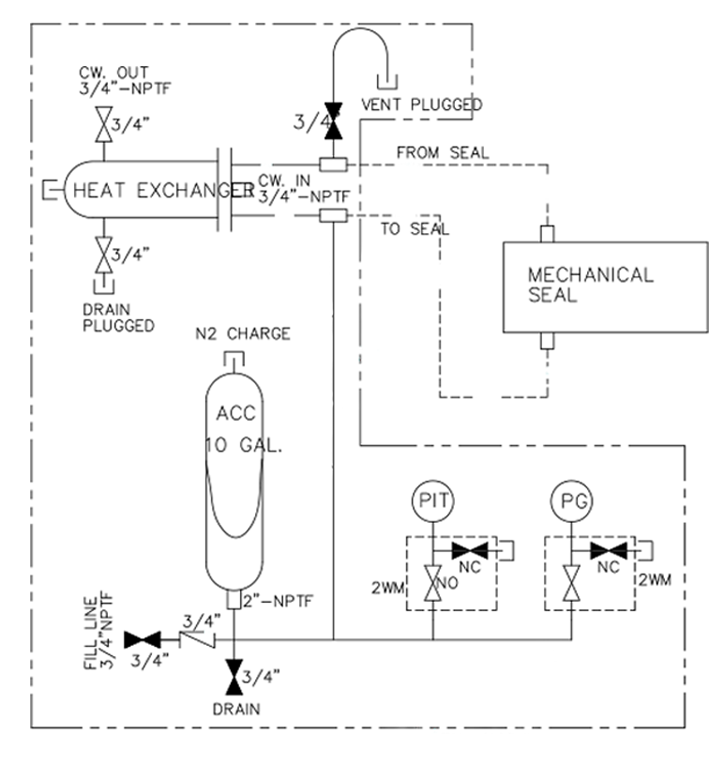

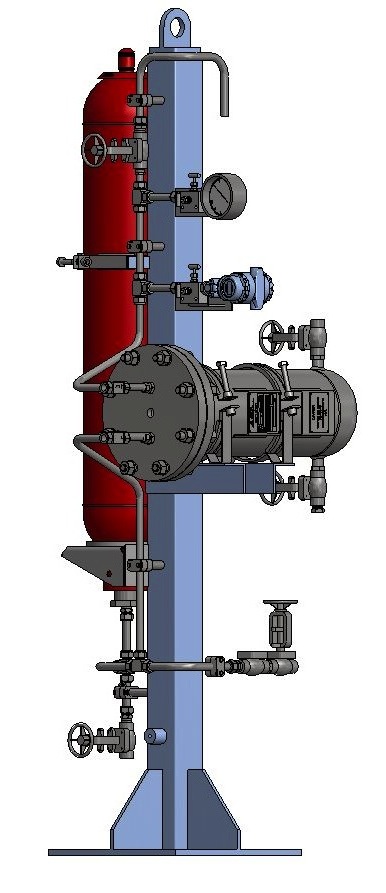

API 682 PLAN 53B

API 682 Plan 53B is used to prevent all leakage produced from the primary inboard seal of a dual pressurized wet mechanical seal arrangement.

The Plan 53B system contains a clean compatible barrier fluid that is pressurized with an inert gas, typically Nitrogen via a bladder accumulator. This system is used in applications where seal chamber pressures exceed 150 psig to eliminate potential gas saturation of the barrier fluid. Unlike other dual pressurized seal systems, Plan 53B operates in a variable pressure range due to barrier fluid consumption. Pressure limits need to be established at the design stage to determine initial bladder pre-charge. A seal cooler is installed to remove heat from this system and a pressure transmitter is used to alarm the system due to barrier volume losses during regular seal operation.

| Standard Design Features | Optional Design Features |

|

|

*All materials used per ASME Section VIII Div. 1